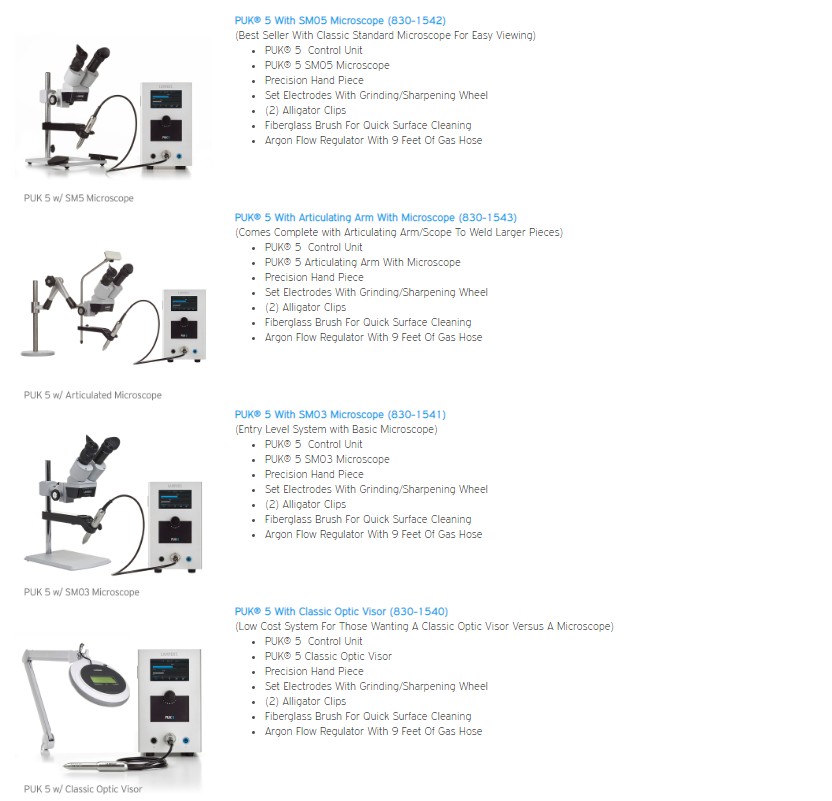

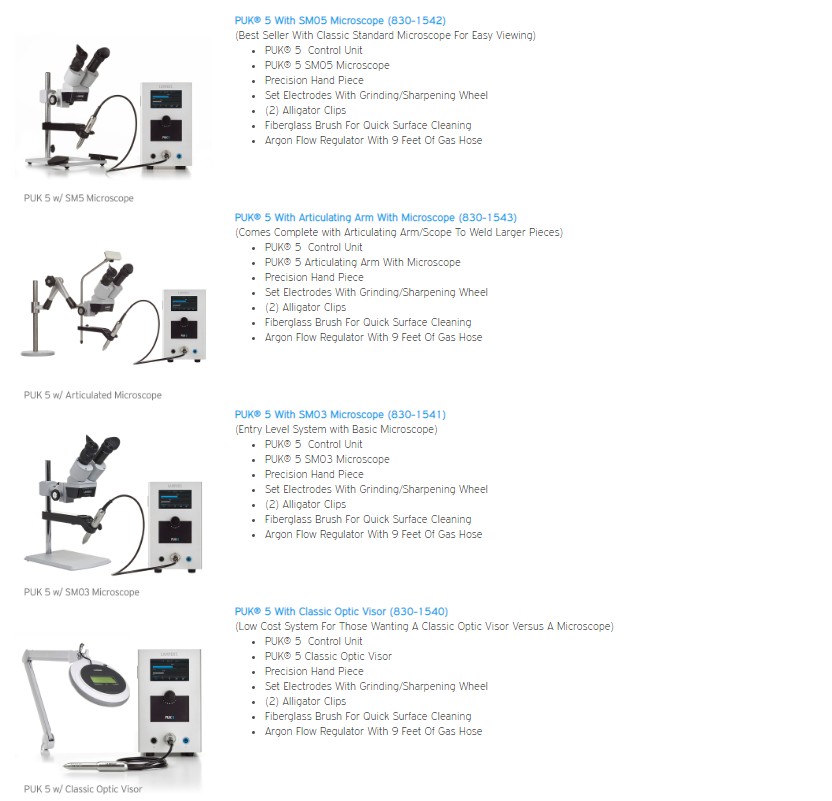

Precision welding at its finest: introducing the PUK® 5 Jewelry Welder.

Select the metal... choose your mode... weld with confidence!

The PUK® 5... developed for goldsmiths.

Weld on findings, easily add metal, weld adjacent to Stones and pearls, weld silver (alloys), fill porosity, attach workpieces prior to soldering, weld seams, and much more - all no problem with the PUK® 5.

Compact and versatile impulse welding device.

The PUK® 5 is very close to laser welding in terms of working method and range of applications. On workpieces with a thickness of 0.2 mm or greater, it is an effortless process to produce robust welds. The PUK® 5 precision welder puts a whole host of possible applications for jewelry production at your fingertips. Structures made from sheet or wire elements can be just as easily done as tack welds and repairs to jewelry parts, restoring missing parts or filling of pores by applying welding wire - and many more options. The PUK® 5 is able to produce anything from the smallest of repairs to volume production, and even the most extraordinary new creations.

PUK®’s operating principle is as simple as it is ingenious:

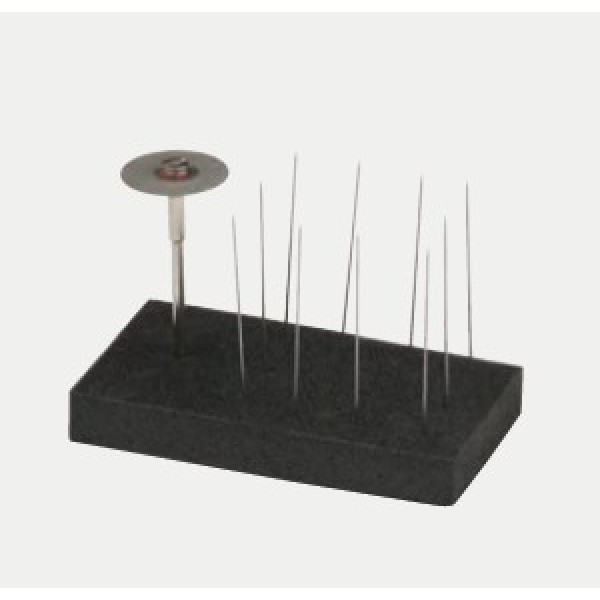

If the tip of the electrode on the welding hand piece touches the workpiece, the welding process starts automatically. At the contact point, under an inert gas atmosphere, a melting process with a diameter of between 0.3 and 3.0 mm takes place (depending on material and setting). In addition to many precious metal alloys such as gold, silver and platinum, many non-ferrous metals such as copper and tin alloys, many steels , titanium and aluminum alloys are suitable for welding. All alloys suitable for laser or TIG welding can also be welded with the PUK® 5.

Facts that speak for themselves.

1. Superior welding characteristics

Consistently reproducible high-quality welding results with all materials suitable for welding

- Precise positioning of the spot welds

- Very low, controllable development of heat

- Welding possible on even the thinnest of materials

- Welding in protective atmosphere

2. Quality "Made in Germany" by Lampert

- 3 year warranty!

- Tested product safety: CE conformity

- DIN CERTCO certified eye protection in all Lampert optic systems

- Very low initial costs and for consumer materials, maintenance-free technology - excellent price/performance ratio

3. User friendly

- Compact size: fits into every workshop

- Simple and intuitive to operate

- Very low initial costs and for consumer materials, maintenance-free technology - excellent price/performance ratio

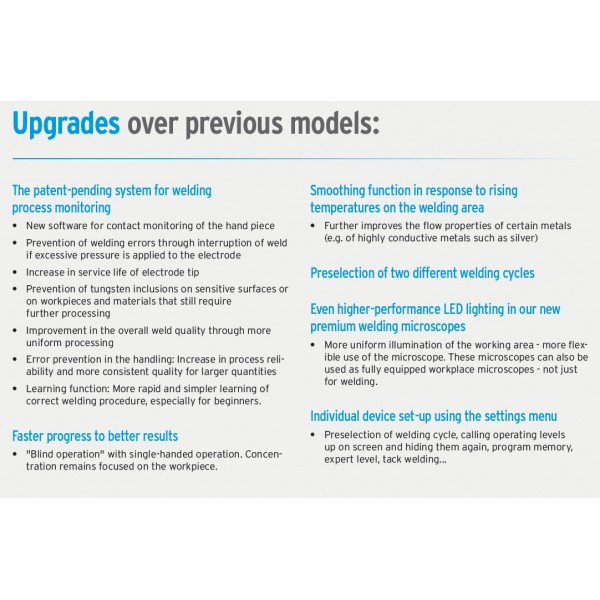

Upgrades over previous models:

The patent-pending system for welding process monitoring

- New software for contact monitoring of the handpiece

- Prevention of welding errors through interruption of weld if excessive pressure is applied to the electrode

- Increase in service life of electrode tip

- Prevention of tungsten inclusions on sensitive surfaces or on workpieces and materials that still require further processing

- Improvement in the overall weld quality through more uniform processing

- Error prevention in the handling: Increase in process reliability and more consistent quality for larger quantities

- Learning function: More rapid and simpler learning of correct welding procedure, especially for beginners.

Faster progress to better results

- "Blind operation" with single-handed operation. Concentration remains focused on the workpiece.

Smoothing function in response to rising temperatures on the welding area

- Further improves the flow properties of certain metals (e.g. of highly conductive metals such as silver)

Preselection of two different welding cycles

Even higher-performance LED lighting in our new premium welding microscopes

- More uniform illumination of the working area - more flexible use of the microscope. These microscopes can also be used as fully equipped workplace microscopes - not just for welding.

Individual device set-up using the settings menu

- Preselection of welding cycle, calling operating levels up on screen and hiding them again, program memory, expert level, tack welding, and more.

The operating concept for the PUK® 5: simple, intuitive, user-friendly.

New look & design, New features, and New upgraded technology.

- Extremely simple touchscreen operation

- Now with slide function!

- Select metal - select welding situation - weld!

- Easily review the optimum setting ranges for the selected welding task

- Pre-set programs for standard metals such as gold, silver and platinum, and for common welding situations

- Setting of parameters for "Power," "Time," and menu navigation with a single rotary controller.

- Setting of "Power" and "Time" also by a swiping action on the high-contrast display.

- Help and assistance functions accessible at any time

- Optimized "Settings" menu with scope on demand for enabling or disabling practical additional functions such as the expert menu with 15 different welding curves, the program memory for 20 proprietary programs or the fix-welding function.

- The selection of basic functions such as lighting, welding sequence or choice of language is a quick and easy process.

- The smoothing function accelerates the weld cycle, increasing the heat generated in the welding zone on workpieces. This can facilitate the welding process, e.g. on highly conductive metals and alloys such as silver or aluminum. The surfaces are easier to smooth and model because of the improvement in flow characteristics. At the same time, this function causes greater heating of the workpiece and should therefore also be used with caution.

- The patent-pending system for welding process monitoring intervenes actively for you if excessive pressure is applied to the tip of the electrode during the welding process, and/or if the workpiece is guided in too rapidly. In this situation, the process is interrupted automatically and an optical signal in the eye protection system signals operator error. This can prevent a welding malfunction from occurring.

- Welding with different levels of contact with the electrode distorts the selected parameters and makes it difficult to obtain consistently uniform welding results. It can cause the electrode get stuck to the workpiece, or can introduce undesirable amounts of tungsten to the surface of the workpiece. This new function improves the total performance of the welding process. It gives rise to more uniform results while also improving the electrode service life, resulting in a more constant quality in your welding results. At the same time, this function helps the newcomer to PUK® to learn from Day One how to work properly with the PUK® 5.

-80x80.jpg)